Inkjet

It has been known for some time that inkjet formulators can use HSP for many purposes. One example of this is from AgfaLabs who, at the HSP50 conference, showed how to use HSP to help formulate water-dispersed inkjet pigments. Their paper can be downloaded from the Conference proceedings, Fri 01B Wuytens.pptx

Here we are grateful to Dr Els Mannekens of ChemStream for allowing us to provide a download of her prize-winning talk at the Inkjet Conference, Neuss/Düsseldorf, 24-25 Oct 2017. The talk covers two important aspects of inkjet.

Here we are grateful to Dr Els Mannekens of ChemStream for allowing us to provide a download of her prize-winning talk at the Inkjet Conference, Neuss/Düsseldorf, 24-25 Oct 2017. The talk covers two important aspects of inkjet.

- How to ensure that the ink particles, either as pigments or as pigments plus dispersants, stay well-suspended in a matrix such as a UV-curable ink.

- How to ensure that the components of your inkjet system are not attacked by the solvents you are using.

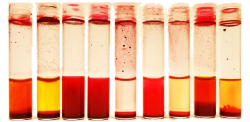

1. From sedimentation tests, as you can see from one of the images from the talk (showing 9 of the 42 solvents used for a magenta pigment), it is easy to build up a picture of "good" (slow sedimentation) and "bad" (fast sedimentation) solvents in order to measure the pigment's HSP via the classic sphere technique. It thus becomes possible to screen different commercial pigments to find which give a close match to the desired UV formulation - the HSP of which can be found within HSPiP by creating a blend of the different acrylates.

1. From sedimentation tests, as you can see from one of the images from the talk (showing 9 of the 42 solvents used for a magenta pigment), it is easy to build up a picture of "good" (slow sedimentation) and "bad" (fast sedimentation) solvents in order to measure the pigment's HSP via the classic sphere technique. It thus becomes possible to screen different commercial pigments to find which give a close match to the desired UV formulation - the HSP of which can be found within HSPiP by creating a blend of the different acrylates.

2. And although one can conduct long-term swelling tests on each polymer component in the inkjet system, it is more efficient to screen for likely solvent/polymer compatibilities and therefore to avoid using such polymers from the start. In the talk, POM is seen as being totally unsuitable for their UV formulations as the acrylates used are inside the POM HSP sphere.

For those who wish to study the talk in detail, it can be download from Inkjet_HSP_Chemstream.pdf